In Brief

-

- The lifting platform mod. PEP 8400 was designed and built to lift a fixed number of operators for maintenance and assistance operations on the truck.

- It consists of a basement, a lifting system and a operative platform.

- The basement is composed of a fixed part linked to the frame of the truck and a moving part connected to it by a thrust-bearing block in order to allow a rotation of 180° of the lifting device.

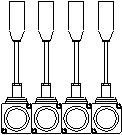

- The fixed part of the basement has four stabilizers, each of them are activated by an double acting oleo dynamic cylinder, which allows a higher stability to the truck when platform is lifted.

Data Sheet

The lifting platform mod. PEP 8400 was designed and built to lift a fixed number of operators for maintenance and assistance operations on the truck.

| Walking plane maximum height | 8,40 m |

| Max load (including 60 kg tools) | 300 kg |

| Maximum number of lifting operators | 3 |

| Max wind speed allowed | 20,58 m/s |

| Maximum inclination allowed | 0° |

| Normal operating power supply | Internal combustion engine |

| Electric system power voltage | 12 V |

| Operating pressure of the oleo dynamic system | 120 bar |

| Emergency power supply | Hand pump |

| Pondered equivalent continuous acoustic pressure level | < 70 dBA |

Reference Norms

The referring normatives used for the designing and manufacturing of the PEP 8400 lifting platform is the European-norm EN 1915 (Aircraft ground support equipment).

Device

The lifting platform is furnished with:

- stabilizers control panel;

- Control panel on the working platform.

Safety Device

- Stabilizers safety block – lifting device: it stops the lifting of the platform in case the stabilizers haven’t been correctly placed on the ground.

- Accidental truck moving during operation: Turns off the truck engine when hand brake is removed, or when the gas pedal is accidentally pushed with stabilizer still in position.

- Maximum pressure of the valve on lifting cylinders: avoids the lifting of the platform in case the maximum weight is exceeded.

- Valve blocking of all the oleo dynamic actuators: avoids accidental movements of the components of the truck in case the flexible connections pipes brake.

- Lifting device safety block – stabilizers: avoids the re-entry of the stabilizers if the lifting device has not been completely moved in position.

Customization

Platforms can be customized accordingly with customer’s needs and with the national laws concerning safety matriculation.

Functionality

The PEP 8400 is made by a basement, a lifting device and working platform.

Lifting Platform

The lifting device consists of two rear and two side pantographers.

All pantographs are composed of six pairs of arms; the side pantographs are guided by two cylinders each, while each rear pantograph is activated by one single cylinder.

The working platform, thanks to the action of a double acting oleo dynamic cylinder, can move horizontally in order to allow a closer approach to the aircraft.

Basement

The basement is composed of a fixed part linked to the frame of the truck and a moving part connected to it by a thrust-bearing block in order to allow a rotation of 180° of the lifting device.

Stabilizers

The fixed part of the basement has four stabilizers, each of them are activated by an double acting oleo dynamic cylinder, which allows a higher stability to the truck when platform is lifted.

Safety lights fitted on upper part of cabin

To comply with some airport rules a special exhaust lead is installed

Lifting Platform

The lifting platform is composed of:

– stabilizers control panel;

– Control panel on the working platform.

The stabilizers’ command panel is on the left side of the truck, behind the driving seat with the following functions:

– Rear right stabilizer;

– Rear left stabilizer;

– Front right stabilizer;

– Front left stabilizer;

Maximum weight capacity 300 Kg

Oleo Dynamic system

The oleo dynamic system comprises of an oleodynamic pump calibrated for a max press of 130 bars, driven by the engine of the vehicle.

Linking engine-pump is obtained by an electromagnetic switch commanded by dedicated switches incorporated in the oleo dynamic distributors.

Max regulating press valve: set the pressure for the operation of the hydraulic system.

Commands Features:

When platform is extended start and shut off engine commands are available.

Emergency hand pump available on ground for emergency operations.

Stabilizers command lever.